Precision and cutting costs are very important in the fast-paced world of industrial buildings. ACE Estimating Services is glad to offer industrial estimating services that are specially designed to meet the needs of industrial projects.

Whether you’re a developer, industrial contractor, or project manager, our knowledge will make sure that your projects are carefully planned, budgeted, and carried out to the greatest standards.

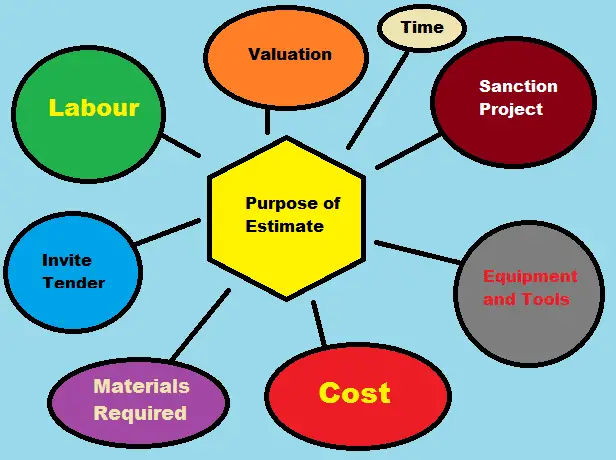

Significance of ACE Industrial Estimating Projects

Preciseness:

ACE industrial estimating services Projects are known for being precise and accurate, which makes sure that project costs are accurate from the start.

Cost Control:

Our estimates help keep project costs down by breaking down costs in great depth, which makes budgeting easier.

Competitive Edge:

Accurate figures give you an edge over other bidders. Also, it raises your chances of getting good contracts.

Risk Mitigation:

Finding possible risks and cost overruns early on lets you take effective steps to reduce those risks, which protects the success of your project.

Quality Assurance:

ACE Estimating Services makes sure that industrial projects meet strict quality standards, which makes the buildings safer and lasts longer.

Timely Completion:

Our forecasts and effective project planning help make sure that projects are finished on time, avoiding costly delays.

Client trust:

Detailed estimates give clients, and investors trust by showing that you are honest and have done good financial planning.

Sustainable Solutions:

We can include eco-friendly and long-lasting features in our forecasts. So, making sure that projects meet environmental standards and save money in the long run.

Comprehensive help:

We offer help in many areas, such as change order management, procurement, and lowering costs, in addition to estimating.

Diverse Knowledge:

ACE Estimating Services works with many different types of industries. These industries include chemical, petrochemical, mining, marine, oil & gas, medicinal, and more.

Industry Best Practices:

We use cutting-edge tools and follow the best practices in our field to give you accurate estimates that are the basis for successful industrial projects.

Project Success:

When manufacturing projects work with ACE Estimating Services, they get accurate estimates, help keep costs down, and expert advice, all of which help the projects succeed overall.

Our Comprehensive Industrial Estimate Services

Here at ACE Estimating Services, we provide a full range of industrial estimating services to meet the complex needs of industry projects. With their cutting-edge technology and knowledge of the industry, our expert estimators give you the tools and information you need to make smart choices for projects to succeed.

1. Comprehensive takeoffs of quantities and cost estimates

Accurate calculations of the amounts of materials needed and the prices of labor for each part of the project. Also, ensure a solid budget base.

Make sure that the best quality standards are met at all times during the lifecycle of your industrial project.

2. Eyewitnesses who are experts

ACE Estimating Services provides expert witnesses who can give fair opinions and judgments to help settle disagreements and back legal cases.

An unbiased look at the project plans, budgets, and paperwork to find mistakes and make sure they are correct.

3. Managing and evaluating bids

Looking over and judging bids to help you pick the best and most affordable choices for your industrial projects.

Help with finding materials and equipment quickly, making the buying process more efficient, and cutting prices as much as possible.

4. Making and going over the change order

Keeping track of changes to project plans, making sure they fit together smoothly and avoiding costs that were not expected.

In-depth studies to find out if your industrial project is possible and workable, reducing risks and unknowns.

5. Analysis of Risk

Finding and evaluating the possible risks that your project might have so that you can take steps to reduce them before they happen.

Figuring out how to make things more efficient and use resources more wisely by checking how productive people and things are.

6. Project Scheduling:

Making and managing project schedules to make sure that work is done on time and that project goals are met.

Keeping an eye on and controlling costs throughout the whole project to make sure the budget doesn’t go over. Value industrial engineering estimating and costing means finding ways to cut costs and making project designs work better.

Our wide range of services gives you the tools you need to make smart choices, lower your risks, and complete industrial projects that are exceptional in their quality, speed, and low cost.

Precision in Every Detail: Your Industrial Estimates of Choice

We have precise Home Builders Estimates and have vast proficiency in softwares. ACE Estimating Services leads the construction industry by using various digital platforms to improve our estimating accuracy, efficiency, and transparency. We strive to improve our software skills to serve our clients better and meet industrial construction estimating standards.

Planswift, Trimble, FastPIPE, FastDUCT:

The ACE Estimating Services staff is experienced in Planswift, Trimble, FastPIPE, and FastDUCT construction estimating software. These tools enable efficient and accurate quantity takeoffs and cost estimates across construction divisions.

Our experience with these software platforms provides accurate and consistent estimates for concrete foundation materials and HVAC ductwork.

FastWRAP, RSMeans, Bluebeam, ConEst:

We also use FastWRAP, RSMeans, Bluebeam, and ConEst. FastWRAP helps us estimate insulating materials. RSMeans, a reliable cost database, improves our estimates to meet industry standards.

Bluebeam streamlines project operations through document management and collaboration. We can mainly generate precise electrical estimates with ConEst to account for every component of your project.

Quest estimation:

Our expertise includes Quest Estimating, a versatile building estimating software. Our flexible technology especially lets us deliver detailed, precise, and customised project estimates.

How Do I Get Started With Ace?

Starting with ACE Estimating Services, it is easy to get the skilled estimating help you need for your construction projects. Start with these steps for our industrial construction estimating menu:

1. Initial Consultation and Project Information Submission:

ACE Estimating Services offers introductory consultations. This consultation allows you to discuss project needs, goals, and obstacles with our expert staff.

When you proceed, you must give detailed project information. Architectural designs, engineering drawings, project requirements, and other project documents are usual.

2. Estimate Generation and Review:

Experienced estimators will start generating thorough project cost estimates. Our estimates are mainly accurate and reliable thanks to superior estimation technologies and industry expertise. We collaborate with you to ensure estimates meet budget and project goals.

3: Project Support and Success:

ACE Estimating Solutions goes beyond estimates. We provide project-long support. Our staff can help you handle construction project complexity with change orders, procurement, scheduling, and cost management.

ACE Estimating Services offers precise and detailed estimates, so call us immediately for a consultation.

Your Partner for Seamless Industrial Projects – Our Portfolio

Chemical, Petrochemical, Mining & Metals:

ACE Estimating Services has multiple clients from many businesses. So, it is done from the complicated processes of chemical and petrochemical plants to the harsh conditions of mines and metal plants.

Marine and Drilling Platforms:

We are also skilled in the seafaring world, where we provide full estimating services for drilling platforms and marine projects.

ACE Estimating Services knows how to handle the complicated parts of marine and drilling projects. Whether they’re figuring out how much shipyard maintenance costs or how much offshore drilling setups cost, all we handle.

Oil & Gas and Pharmaceutical Plants:

We do industrial estimating for the oil & gas business and the pharmaceutical industry.

Our detailed cost projections cover building and maintaining oil refineries, gas processing plants, and factories that make medicines. When working in these important fields, we know how important accuracy and safety are.

Food Processing and Hydrocarbon Processing:

ACE Estimating Services also does work in the food processing industry. We carefully estimate how much it will cost to build and maintain food production facilities.

We are also very good at hydrocarbon processing jobs, where we estimate the costs of extracting and processing hydrocarbon resources, which is a very important job.

Water treatment plants, biofuels, and more:

We work on projects in a lot of different industries, such as wastewater treatment plants, refinery projects, and refrigeration facilities. Furthermore, we do pumping stations, paper and pulp mills, polymer making, fertilizer production, power generation facilities, and packaging plants.

ACE Estimating Services is dedicated to providing precise and thorough estimates. That helps build and maintain important structures in a wide range of industries.

Because they have so much experience and knowledge in industrial estimating services, ACE Estimating Services is a reliable partner in many fields.

We make sure we meet the specific needs and challenges of each sector by focusing on accuracy, efficiency, and knowledge of the business. Further, this helps industrial projects around the world succeed.

What Makes ACE Estimating Services the Best Option for Industrial Projects?

ACE Estimating Services is pleased to offer industrial estimating services that are specially designed to meet the needs of industrial projects. Accurate Project Budgeting: Our Industrial Estimates give you full, accurate, and trustworthy cost breakdowns. So that you can make realistic project budgets right from the start.

Competitive Advantage:

Our thorough estimates give you an edge in the industrial sector. Also, it lets you make winning bids and land important contracts.

Keep an eye on costs:

Industrial projects often have big budgets. We help you keep costs under control throughout the whole project. So your investments get the best return possible.

Complexity Management:

Industrial projects can be hard to understand because they need specialized tools and methods. ACE Estimating Services is great at handling the details so that your job goes smoothly.

On-Time Project Finish:

Our experience with project timing helps make sure that your industrial projects are finished on time. Moreover, we avoid costly delays and service interruptions.

Sustainable Solutions:

We can include eco-friendly and long-lasting features in your quotes. So, make sure that your business projects meet environmental standards and save you money in the long run.

Risk Mitigation:

Finding possible risks and cost overruns early on in the planning process lets you come up with good ways to protect your project.

Client Trust:

Our detailed estimates give your clients or buyers faith in you. Also, showing that you care about being open and smart with your money.

Specialized Knowledge:

ACE Estimating Services has worked in many different industries, such as manufacturing, transportation, energy, and more. This indeed means that we know how to meet the specific needs of your business.

Comprehensive help:

We offer help in many areas, such as change order management, procurement, and lowering costs, in addition to estimating.

Get Comprehensive Industrial Estimating Solutions Today

Industrial Structural Steel Estimating

ACE Estimating Services’ industrial structural steel estimating knowledge encompasses a wide range of components. That is needed for industrial facility structural integrity and functionality.

ExpertiseOur estimators carefully measure rebar, plumbing, roofing, siding, louvers, platforms, railings, ladders, and grating. These components are essential to industrial structural strength, safety, and efficiency.

Our precise industrial piping estimating software mainly helps us achieve industrial project quality standards and produce realistic project budgets. Also, we enable cost-effective construction.

ACE Estimating Services provides precise and dependable estimates for strengthening steel for concrete structures or complex piping networks. This is indeed laying the groundwork for successful industrial projects.

Industrial Mechanical Estimation

Our skilled mechanical estimators at ACE Estimating Services can takeoff a wide range of industrial mechanical components with precision.

ExpertiseOur expertise includes ductwork, piping, insulation, HVAC, sprinkler, and gas material conveying. Moreover, we are also experts in crushing, mechanical equipment, welding, instrumentation and controls, pressure vessels, and mechanical alterations estimates.

Industrial processes depend on these mechanical systems for efficiency, safety, and reliability. Our estimators calculate every component, from massive ducting to complex sensors and controls, precisely. ACE Estimating Services provides accurate mechanical estimates to help industrial projects succeed throughout development.

Industrial Electrical Estimation

ACE industrial electrical estimating services expertise covers a variety of systems essential to industrial facility operation.

ExpertiseWe specialize in precision electrical takeoffs for low-voltage control, instrumentation, and emergency service. Also, we estimate power distribution, conveyance, power and lighting, solar power installations, geothermal systems, and ground-up projects.

Industrial processes depend on these electrical systems for efficiency, safety, and functionality.